From the New York Times:

A 3-D printer, which has nothing to do with paper printers, creates an object by stacking one layer of material — typically plastic or metal — on top of another, much the same way a pastry chef makes baklava with sheets of phyllo dough.

The technology has been radically transformed from its origins as a tool used by manufacturers and designers to build prototypes.

These days it is giving rise to a string of never-before-possible businesses that are selling iPhone cases, lamps, doorknobs, jewelry, handbags, perfume bottles, clothing and architectural models. And while some wonder how successfully the technology will make the transition from manufacturing applications to producing consumer goods, its use is exploding.

A few promo videos for 3-D printers:

These are all billed as a way to build prototypes, but it’s not a far leap to think this will potentially be a way in the future for people to print out products. Complicated, yes, but not impossible given this head start.

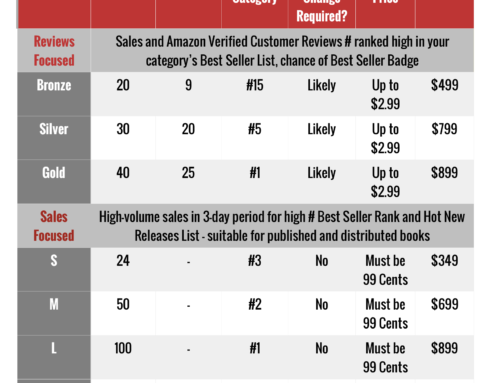

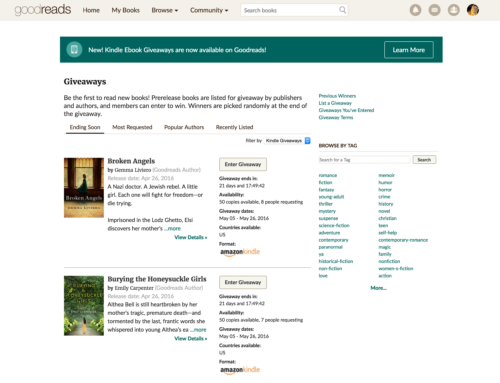

Get an Editorial Review | Get Amazon Sales & Reviews | Get Edited | Get Beta Readers | Enter the SPR Book Awards | Other Marketing Services

What I find even more interesting are self-replicating 3D printers like the one at http://reprap.org – they are 3D printers that can print plastic parts, but are also made of plastic parts, so they can produce copies of themselves. Another step closer to robotic assembly lines producing robots.

Alan Alda did a series that included this about five years ago. It was mind-blowing then, and it’s mind-blowing now. Unless my circuits are scrambled (good chance), he had a bike created by one of these machines. Another machine he showed was an early version of the Espresso Book Machine, proving that that series was on to something real.